SMARTTRACK™ Communication System

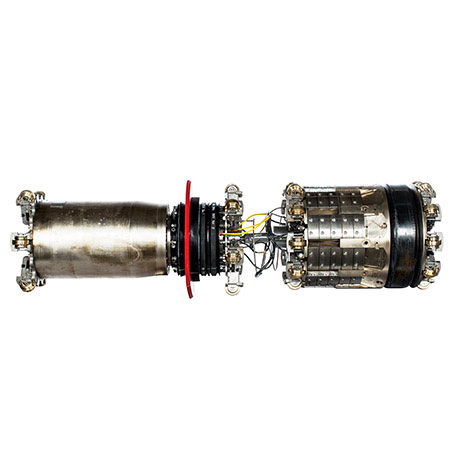

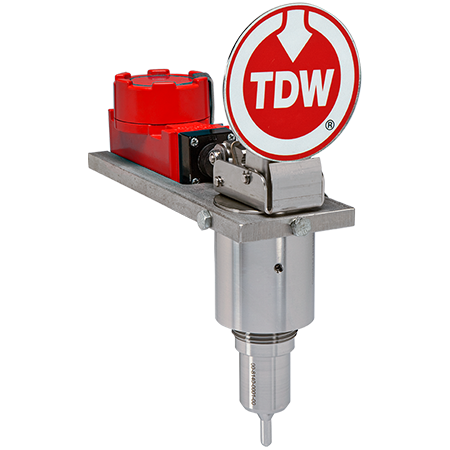

The SmartTrack™ two-way communication system detects and pinpoints the exact location of multiple pigs or inline tools traveling through any pipeline medium. This system was developed for use offshore, both topside and subsea. It can be used to track and locate any moving or stationary pig or tool equipped with a SmartTrack transponder.

Specifications

- Each transponder can uniquely track up to 16 different pigs in one run

- Tracking is possible through pipelines of wall thickness up to 80 mm (approx. 3 inches)

- Two-way communication is possible through wall thickness of up to 65 mm (approx. 2.5 inches)

- Enables pig or tool positioning with +/- 25 mm (1-inch) accuracy

Key Features

- Enables two-way, through-wall communication

- Three basic system components (transponders, transceivers and Personal Digital Assistant (PDA)/SmartPhone/Personal Computer (PC))

- ATEX/IECEx-certified equipment available

- Serial communication can be greatly extended through the use of subsea communication skids, topside radio link and remote monitoring through satellite or GSM (4G)

- Transmits local pressure and temperature readings and alerts personnel to changes in pipeline conditions

- Signal frequency and signal strength can be varied to allow tracking of pigs or inline tools moving at high speeds

- To conserve battery life, the transponder can be switched to dormant mode for up to several years and reactivated to pinging mode when required

Common Applications

- Detecting and confirming the passage of pigs or tools inside pipelines

- Confirming pig or inline tool position to facilitate valve closure

- Confirming the departure/arrival of a pig or inline tool from/at the pig trap

- Sole tracking system for SmartPlug inline isolation operations

The SmartTrack™ two-way communication system detects and pinpoints the exact location of multiple pigs or inline tools traveling through any pipeline medium. This system was developed for use offshore, both topside and subsea. It can be used to track and locate any moving or stationary pig or tool equipped with a SmartTrack transponder.

Specifications

- Each transponder can uniquely track up to 16 different pigs in one run

- Tracking is possible through pipelines of wall thickness up to 80 mm (approx. 3 inches)

- Two-way communication is possible through wall thickness of up to 65 mm (approx. 2.5 inches)

- Enables pig or tool positioning with +/- 25 mm (1-inch) accuracy

Key Features

- Enables two-way, through-wall communication

- Three basic system components (transponders, transceivers and Personal Digital Assistant (PDA)/SmartPhone/Personal Computer (PC))

- ATEX/IECEx-certified equipment available

- Serial communication can be greatly extended through the use of subsea communication skids, topside radio link and remote monitoring through satellite or GSM (4G)

- Transmits local pressure and temperature readings and alerts personnel to changes in pipeline conditions

- Signal frequency and signal strength can be varied to allow tracking of pigs or inline tools moving at high speeds

- To conserve battery life, the transponder can be switched to dormant mode for up to several years and reactivated to pinging mode when required

Common Applications

- Detecting and confirming the passage of pigs or tools inside pipelines

- Confirming pig or inline tool position to facilitate valve closure

- Confirming the departure/arrival of a pig or inline tool from/at the pig trap

- Sole tracking system for SmartPlug inline isolation operations